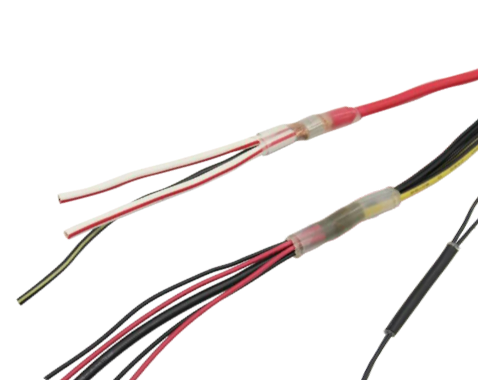

Adhesive lined heat shrink tubing with environmental sealing capability for a wide variety of electrical applications, including automotive and marine wire harness, wire splices, breakouts, and connector-to-cable transitions.

Features

| Size |

As Supplied |

After Recovery |

|

Standard Package |

||

|---|---|---|---|---|---|---|

|

Inch |

mm |

Internal Diameter mm |

Internal Diameter mm |

Total Wall Thickness mm |

Adhesive Thickness mm |

Spool Length M/spool |

|

1/16 |

1.6 |

1.6 |

0.8 |

0.60±0.30 |

0.30±0.2 |

200 |

|

3/32 |

2.4 |

2.4 |

1.2 |

0.70±0.30 |

0.35±0.2 |

200 |

|

1/8 |

3.2 |

3.2 |

1.6 |

0.70±0.30 |

0.35±0.2 |

200 |

|

3/16 |

4.8 |

4.8 |

2.4 |

0.80±0.30 |

0.40±0.2 |

100 |

|

1/4 |

6.4 |

6.4 |

3.2 |

0.80±0.30 |

0.40±0.2 |

100 |

|

5/16 |

7.9 |

7.9 |

3.9 |

0.90±0.30 |

0.45±0.2 |

100 |

|

3/8 |

9.5 |

9.5 |

4.8 |

0.90±0.30 |

0.45±0.2 |

50 |

|

1/2 |

12.7 |

12.7 |

6.4 |

0.95±0.40 |

0.45±0.2 |

1.22 OR 25M/Roll |

|

5/8 |

15.9 |

15.9 |

7.9 |

0.95±0.40 |

0.45±0.2 |

1.22 OR 25M/Roll |

|

3/4 |

19.1 |

19.1 |

9.5 |

1.00±0.40 |

0.45±0.2 |

1.22 OR 25M/Roll |

|

1 |

25.4 |

25.4 |

12.7 |

1.10±0.40 |

0.50±0.2 |

1.22 OR 25M/Roll |

|

1 1/4 |

31.8 |

31.8 |

15 |

1.15±0.40 |

0.50±0.2 |

1.22 OR 25M/Roll |

|

1 1/2 |

38.1 |

38.1 |

19 |

1.25±0.40 |

0.50±0.2 |

1.22 OR 25M/Roll |

|

1/ 3/4 |

44.5 |

44.5 |

22 |

1.35±0.40 |

0.55±0.2 |

1.22 OR 25M/Roll |

|

2 |

50.8 |

50.8 |

25.4 |

1.50±0.40 |

0.60±0.2 |

1.22 OR 25M/Roll |

Property |

Test Method |

Standard |

Typical Performance |

|---|---|---|---|

Tensile Strengtn(MPa) |

ASTM D2671 |

≥10.4 |

11.5 |

Elongation(%) |

ASTM D2671 |

≥300 |

450 |

Tensile Strengtn after aging (MPa) |

UL224 158℃X168hr |

≥7.3 |

8.5 |

Elongation after aging(%) |

UL224 158℃X168hr |

≥200 |

350 |

Dieletric strength(kv/mm) |

IEC 60243 |

≥15 |

17.5 |

Volume resistivity(Ω.cm) |

IEC 60093 |

≥1X101 4 |

2.5X101 4 |

Flammability |

ASTM D2671B |

||

Property |

Test Method |

Stantard |

|---|---|---|

Water Absorption |

ASTM D570 |

≤0.2% |

Sofening Point(℃) |

ASTM E28 |

90±5 |

Strength of pearing(PE) |

ASTM D 1000 |

120N/25mm |

Strength of pearing(AL) |

ASTM D 1000 |

80N/25mm |

SBRS-(2X)QF Adhesive-lined Heat-shrinkable Tubing is specially designed for Automotive Oil-pipe Protection, providing preventive protection to break line, fuel line, hydraulic line and other metal pipeline which is subject to bending or clamping during manufacturing, installation or operation.

Size |

Expanded |

After Recovery |

Standard Package |

||

|---|---|---|---|---|---|

mm |

Internal Diameter Min(mm) |

Internal Diameter Max(mm) |

Total Wall Thickness Nom(mm) |

Adhesive Thickness Nom(mm) |

Spool Length M/spool |

Φ6.0 |

6 |

4.5 |

1.20±0.20 |

0.20±0.05 |

300 |

Φ8.0 |

8 |

6.1 |

1.30±0.20 |

0.20±0.05 |

200 |

Φ11.0 |

11 |

7.1 |

1.30±0.20 |

0.20±0.05 |

200 |

Φ13.0 |

13 |

9.8 |

1.30±0.20 |

0.20±0.05 |

100 |

Φ15.0 |

15 |

11.5 |

1.30±0.20 |

0.20±0.05 |

100 |

Property |

Test Method |

Standard Performance |

|---|---|---|

Tensile Strengtn(MPa) |

ASTM D2671 |

≥12 |

Elongation(%) |

ASTM D2671 |

≥300 |

Longitudinal change |

ASTM D2671 |

|

Tensile strength after aging(MPa) |

120℃X24h |

≥12 |

140℃,10min,2kg/cm2 ,loaded 5min |

≤60% |

|

ASTM D 746 |

||

Impact resistance to fall |

Room temperature&-40℃X30min, impacted by a weight of 200g, 0.5m high |

no cracking |

ASTM D 1693 |

no cracking |

|

Chemical reagents resistance: 0.1mol/L H2SO4,0.1mol/L NaOH, Brake fluid, Engine oil, Gasoline |

No abnormal in appearance |

20℃,120hr |

Property |

Test Method |

Standard |

|---|---|---|

Water Absorption |

ASTM D570 |

<0.5% |

Sofening Point(℃) |

ASTM E28 |

105±5 |

Strength of pearing(AL) |

ASTM D 1000 |

120N/25mm |

Strength of pearing(PE) |

ASTM D 1000 |

80N/25mm |

Adhesive lined heat shrink tubing with environmental sealing capability for a wide variety of electrical applications, including automotive and marine wire harness, wire splices, breakouts, and connector-to-cable transitions.

|

Size |

Expanded |

After Recovery |

|

Standard Package |

||

|---|---|---|---|---|---|---|

|

Inch |

|

Internal Diameter mm |

Internal Diameter mm |

Total Wall Thickness mm |

Adhesive Thickness mm |

Spool Length M/spool |

|

3/32 |

2.4 |

2.4 |

0.8 |

0.80±0.30 |

0.40±0.20 |

200 |

|

1/8 |

3.2 |

3.2 |

1.0 |

0.90±0.30 |

0.40±0.20 |

200 |

|

3/16 |

4.8 |

4.8 |

1.6 |

1.05±0.30 |

0.40±0.20 |

100 |

|

1/4 |

6.4 |

6.4 |

2.2 |

1.25±0.30 |

0.45±0.20 |

100 |

|

5/16 |

7.9 |

7.9 |

2.7 |

1.35±0.30 |

0.50±0.20 |

100 |

|

3/8 |

9.5 |

9.5 |

3.2 |

1.45±0.30 |

0.50±0.20 |

50 |

|

1/ 2 |

12.7 |

12.7 |

4.2 |

1.65±0.30 |

0.50±0.20 |

1.22 OR 25M/Roll |

|

5/8 |

15 |

15 |

5.2 |

1.80±0.30 |

0.55±0.30 |

1.22 OR 25M/Roll |

|

3/4 |

19.1 |

19.1 |

6.3 |

1.95±0.30 |

0.60±0.30 |

1.22 OR 25M/Roll |

|

1 |

25.4 |

25.4 |

8.5 |

2.00±0.40 |

0.60±0.30 |

1.22 OR 25M/Roll |

|

|

30 |

30 |

10.2 |

2.15±0.40 |

0.65±0.30 |

1.22 OR 25M/Roll |

|

|

39 |

39 |

13.5 |

2.45±0.40 |

0.60±0.30 |

1.22 OR 25M/Roll |

|

2 |

50 |

50 |

17 |

2.75±0.40 |

0.75±0.30 |

1.22 OR 25M/Roll |

|

5/2 |

64 |

64 |

21 |

3.05±0.40 |

0.80±0.30 |

1.22 OR 25M/Roll |

|

3 |

75 |

75 |

25 |

3.05±0.40 |

1.05±0.40 |

1.22 OR 25M/Roll |

|

7/2 |

90 |

90 |

30 |

3.10±0.50 |

1.05±0.40 |

1.22 OR 25M/Roll |

|

4 |

100 |

100 |

34 |

3.10±0.50 |

1.05±0.40 |

1.22 OR 25M/Roll |

|

5 |

125 |

125 |

42 |

3.10±0.50 |

1.10±0.40 |

1.22 OR 25M/Roll |

Property |

Test Method |

Standard |

Typical Performance |

|---|---|---|---|

Tensile Strengtn(MPa) |

ASTM D2671 |

≥10.4 |

11.5 |

Elongation(%) |

ASTM D2671 |

≥300 |

450 |

Tensile Strengtn after aging (MPa) |

Ul224 158℃X168hr |

≥7.3 |

8.5 |

Elongation after aging(%) |

Ul224 158℃X168hr |

≥200 |

350 |

Flammability |

ASTM D2671B |

||

Dieletric strength(kV/mm) |

IEC 60243 |

≥15 |

17.5 |

Volume resistivity(Ω.cm) |

IEC 60093 |

≥1X101 4 |

2.5X101 4 |

Property |

Test Method |

Stantard |

|---|---|---|

Water Absorption |

ASTM D570 |

<0.2% |

Sofening Point(℃) |

ASTM E28 |

90±5 |

Strength of pearing(PE) |

ASTM D 1000 |

120N/25mm |

Strength of pearing(AL) |

ASTM D 1000 |

80N/25mm |

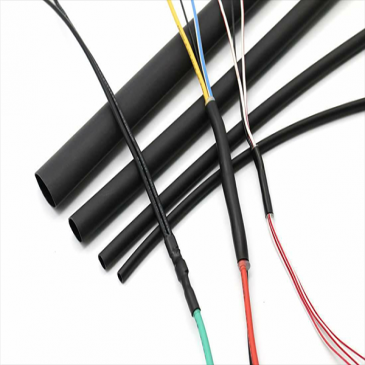

Flexible, Thick Adhesive-Lined Dual Wall Heat-Shrink Tubing is manufactured by co-extrusion of polyolefin and hot-melt adhesive. Designed to provide both insulation and sealing for protected articles, Used to protect bundles wires and metal tubes against water and moisture.

Size |

Expanded |

After Recovery |

Standard Package |

|||

|---|---|---|---|---|---|---|

|

Inch |

mm |

Internal Diameter mm |

Internal Diameter mm |

Total Wall Thickness mm |

Adhesive Thickness mm |

Spool Length M/spool |

|

1/8 |

3.2 |

3.2 |

1.0 |

0.90±0.30 |

0.45±0.20 |

200 |

|

3/16 |

4.8 |

4.8 |

1.6 |

1.20±0.30 |

0.55±0.20 |

100 |

|

1/4 |

6.4 |

6.4 |

2.2 |

1.25±0.30 |

0.55±0.20 |

100 |

|

5/16 |

7.9 |

7.9 |

2.7 |

1.35±0.30 |

0.65±0.20 |

100 |

|

3/8 |

9.5 |

9.5 |

3.2 |

1.35±0.30 |

0.65±0.20 |

50 |

|

1/2 |

12.7 |

12.7 |

4.2 |

1.55±0.40 |

0.75±0.20 |

1.22 OR 25M/Roll |

|

5/8 |

15.0 |

15.0 |

5.2 |

1.65±0.40 |

0.75±0.20 |

1.22 OR 25M/Roll |

|

3/4 |

19.1 |

19.1 |

6.3 |

1.90±0.40 |

0.85±0.20 |

1.22 OR 25M/Roll |

|

1 |

25.4 |

25.4 |

8.5 |

2.00±0.40 |

0.90±0.20 |

1.22 OR 25M/Roll |

|

5/4 |

30.0 |

30.0 |

10.2 |

2.05±0.40 |

0.90±0.20 |

1.22 OR 25M/Roll |

|

|

38.1 |

38.1 |

13.5 |

2.35±0.40 |

1.05±0.20 |

1.22 OR 25M/Roll |

Property |

Test Method |

Standard |

Typical Performance |

|---|---|---|---|

Tensile Strengtn(MPa) |

ASTM D2671 |

≥10.4 |

11 |

Elongation(%) |

ASTM D2671 |

≥300 |

450 |

Tensile Strengtn after aging (MPa) |

Ul224 158℃X168hr |

≥7.3 |

8.5 |

Elongation after aging(%) |

Ul224 158℃X168hr |

≥200 |

350 |

Dieletric strength(kV/mm) |

IEC 60243 |

≥15 |

17.5 |

Volume resistivity(Ω.cm) |

IEC 60093 |

≥1X101 4 |

2.5X101 4 |

Property |

Test Method |

Standard |

|---|---|---|

Water Absorption |

ASTM D570 |

<0.2% |

Sofening Point(℃) |

ASTM E28 |

90±5 |

Strength of pearing(PE) |

ASTM D 1000 |

120N/25mm |

Strength of pearing(AL) |

ASTM D 1000 |

80N/25mm |

Adhesive lined heat shrink tubing with environmental sealing capability for a wide variety of electrical applications, including automotive and marine wire harness, wire splices, breakouts, and connector-to-cable transitions.

Size |

Expanded |

After Recovery |

Standard Package |

|||

|---|---|---|---|---|---|---|

Inch |

mm |

Internal Diameter mm |

Internal Diameter mm |

Total Wall Thickness mm |

Adhesive Thickness mm |

Spool Length M/spool |

3/32 |

2.4 |

2,4 |

0.8 |

0.85±0.15 |

0.40±0.10 |

200 |

1/8 |

3.2 |

3,2 |

1.0 |

0.95±0.15 |

0.40±0.10 |

200 |

3/16 |

4.8 |

4,8 |

1.6 |

1.10±0.15 |

0.40±0.10 |

100 |

1/4 |

6.4 |

6,4 |

2.2 |

1.20±0.15 |

0.45±0.12 |

100 |

5/16 |

7.9 |

7,9 |

2.7 |

1.35±0.15 |

0.50±0.12 |

100 |

3/8 |

9.5 |

9,5 |

3.2 |

1.45±0.20 |

0.50±0.12 |

50 |

1/ 2 |

12.7 |

12,7 |

4.2 |

1.70±0.20 |

0.50±0.12 |

1.22 OR 25M/Roll |

5/8 |

15 |

15 |

5.2 |

1.80±0.20 |

0.55±0.15 |

1.22 OR 25M/Roll |

3/4 |

19.1 |

19,1 |

6.3 |

2.00±0.20 |

0.55±0.15 |

1.22 OR 25M/Roll |

1 |

25.4 |

25,4 |

8.5 |

2.10±0.25 |

0.55±0.15 |

1.22 OR 25M/Roll |

30 |

30 |

10.2 |

2.20±0.25 |

0.60±0.15 |

1.22 OR 25M/Roll |

|

39 |

39 |

13.5 |

2.40±0.25 |

0.60±0.15 |

1.22 OR 25M/Roll |

|

2 |

50 |

50 |

17 |

2.70±0.25 |

0.70±0.15 |

1.22 OR 25M/Roll |

5/2 |

64 |

64 |

21 |

3.00±0.30 |

0.70±0.15 |

1.22 OR 25M/Roll |

3 |

75 |

75 |

25 |

3.00±0.30 |

1.00±0.20 |

1.22 OR 25M/Roll |

7/2 |

90 |

90 |

30 |

3.00±0.30 |

1.00±0.20 |

1.22 OR 25M/Roll |

4 |

100 |

100 |

34 |

3.00±0.30 |

1.00±0.20 |

1.22 OR 25M/Roll |

5 |

125 |

125 |

42 |

3.00±0.30 |

1.00±0.20 |

1.22 OR 25M/Roll |

Property |

Test Method |

Standard |

|

|---|---|---|---|

Tensile Strengtn(MPa) |

ASTM D2671 |

≥10.4 |

|

Elongation(%) |

ASTM D2671 |

≥300 |

|

Tensile Strengtn after aging (MPa) |

Ul224 158℃X168hr |

≥7.3 |

|

Elongation after aging(%) |

Ul224 158℃X168hr |

≥200 |

|

Flammability |

ASTM D2671B |

||

Dieletric strength(kV/mm) |

IEC 60243 |

≥15 |

|

Volume resistivity(Ω.cm) |

IEC 60093 |

≥1X101 4 |

|

Property |

Test Method |

Standard |

|---|---|---|

Water Absorption |

ASTM D570 |

<0.5 |

Sofening Point(℃) |

ASTM E28 |

90±5 |

Strength of pearing(PE) |

ASTM D 1000 |

120N/25mm |

Strength of pearing(AL) |

ASTM D 1000 |

80N/25mm |

Adhesive lined heat shrink tubing ideal for applications where both exceptional flame retardancy and environmental sealing capabilities are required

|

Size |

Expanded |

After Recovery |

Standard Package |

|||

|---|---|---|---|---|---|---|

|

Inch |

mm |

Internal Diameter mm |

Internal Diameter mm |

Total Wall Thickness mm |

Adhesive Thickness mm |

Spool Length M/spool |

|

1/8 |

3.2 |

3.2 |

1.0 |

0.90±0.30 |

0.40±0.20 |

200 |

|

3/16 |

4.8 |

4.8 |

1.6 |

1.05±0.30 |

0.40±0.20 |

100 |

|

1/4 |

5.4 |

5.4 |

2.2 |

1.25±0.30 |

0.45±0.20 |

100 |

|

5/16 |

7.9 |

7.9 |

2.7 |

1.35±0.30 |

0.45±0.20 |

100 |

|

3/8 |

9.5 |

9.5 |

3.2 |

1.45±0.30 |

0.50±0.20 |

50 |

|

1/ 2 |

12.7 |

12.7 |

4.2 |

1.650±0.30 |

0.50±0.20 |

1.22 OR 25M/Roll |

|

5/8 |

15 |

15 |

5.2 |

1.80±0.30 |

0.55±0.30 |

1.22 OR 25M/Roll |

|

3/4 |

19.1 |

19.1 |

6.3 |

1.95±0.30 |

0.60±0.30 |

1.22 OR 25M/Roll |

|

1 |

25.4 |

25.4 |

8.5 |

2.00±0.40 |

0.60±0.30 |

1.22 OR 25M/Roll |

|

|

30 |

30 |

10.2 |

2.15±0.40 |

0.65±0.30 |

1.22 OR 25M/Roll |

|

|

39 |

39 |

13.5 |

2.45±0.40 |

0.75±0.30 |

1.22 OR 25M/Roll |

|

2 |

50 |

50 |

17.0 |

2.75±0.40 |

0.80±0.30 |

1.22 OR 25M/Roll |

|

Size |

Expanded |

After Recovery |

Standard Package |

|||

|---|---|---|---|---|---|---|

|

Inch |

mm |

Internal Diameter mm |

Internal Diameter mm |

Total Wall Thickness mm |

Adhesive Thickness mm |

Spool Length M/spool |

|

5/32 |

4.0 |

4,0 |

1.0 |

1.05±0.30 |

0.50±0.20 |

200 |

|

1/4 |

6.0 |

6,0 |

1.5 |

1.15±0.30 |

0.50±0.20 |

100 |

|

5/16 |

8.0 |

8,0 |

2.0 |

1.55±0.30 |

0.60±0.25 |

50 |

|

1/ 2 |

12.0 |

12,0 |

3.0 |

1.75±0.30 |

0.60±0.25 |

1.22 OR 25M/Roll |

|

5/8 |

16.0 |

16,0 |

4.0 |

2.00±0.35 |

0.70±0.30 |

1.22 OR 25M/Roll |

|

25/32 |

20.0 |

20,0 |

5.0 |

2.30±0.40 |

0.70±0.30 |

1.22 OR 25M/Roll |

|

1 |

24.0 |

24,0 |

6.0 |

2.60±0.40 |

0.75±0.30 |

1.22 OR 25M/Roll |

|

|

32.0 |

32,0 |

8.0 |

3.00±0.50 |

0.90±0.30 |

1.22 OR 25M/Roll |

|

2 |

52.0 |

52,0 |

13.0 |

3.35±0.50 |

0.95±0.30 |

1.22 OR 25M/Roll |

Property |

Test Method |

Standard |

Typical Performance |

|---|---|---|---|

Tensile Strengtn(MPa) |

ASTM D2671 |

≥12 |

12.5 |

Elongation(%) |

ASTM D2671 |

≥300 |

450 |

Tensile Strengtn after aging (MPa) |

≥8.4 |

8.5 |

|

Elongation after aging(%) |

≥100 |

350 |

|

Dieletric strength(kv/mm) |

IEC 60243 |

≥15 |

17.5 |

Volume resistivity(Ω.cm) |

IEC 60093 |

≥1X101 4 |

2.5X101 4 |

Property |

Test Method |

Standard |

|---|---|---|

Water Absorption |

ASTM D570 |

<0.2% |

Sofening Point(℃) |

ASTM E28 |

90±5 |

Strength of pearing(PE) |

ASTM D 1000 |

120N/25mm |

Strength of pearing(AL) |

ASTM D 1000 |

80N/25mm |

Adhesive lined heat shrink tubing with environmental sealing capability for a wide variety of electrical applications, including automotive and marine wire harness, wire splices, breakouts, and connector-to-cable transitions.

|

Size |

Expanded |

After Recovery |

Standard Package |

|||

|---|---|---|---|---|---|---|

|

Inch |

mm |

Internal Diameter mm |

Internal Diameter mm |

Total Wall Thickness mm |

Adhesive Thickness mm |

Spool Length M/spool |

|

5/32 |

4.0 |

4.0 |

1.0 |

1.05±0.30 |

0.50±0.30 |

200 |

|

1/4 |

6.0 |

6.0 |

1.5 |

1.15±0.30 |

0.50±0.30 |

100 |

|

5/16 |

8.0 |

8.0 |

2.0 |

1.55±0.30 |

0.60±0.30 |

50 |

|

1/ 2 |

12.0 |

12.0 |

3.0 |

1.75±0.30 |

0.60±0.30 |

1.22 OR 25M/Roll |

|

5/8 |

16.0 |

16.0 |

4.0 |

2.00±0.30 |

0.70±0.30 |

1.22 OR 25M/Roll |

|

25/32 |

20.0 |

20.0 |

5.0 |

2.30±0.40 |

0.70±0.30 |

1.22 OR 25M/Roll |

|

1 |

24.0 |

24.0 |

6.0 |

2.60±0.40 |

0.75±0.30 |

1.22 OR 25M/Roll |

|

|

32.0 |

32.0 |

8.0 |

3.00±0.40 |

0.90±0.30 |

1.22 OR 25M/Roll |

|

2 |

52.0 |

52.0 |

13.0 |

3.35±0.50 |

0.95±0.30 |

1.22 OR 25M/Roll |

Property |

Test Method |

Standard |

Typical Performance |

|---|---|---|---|

Tensile Strengtn(MPa) |

ASTM D2671 |

≥10.4 |

11.5 |

Elongation(%) |

ASTM D2671 |

≥300 |

450 |

Tensile Strengtn after aging (MPa) |

Ul224 158℃X168hr |

≥7.3 |

8.5 |

Elongation after aging(%) |

Ul224 158℃X168hr |

≥200 |

350 |

Flammability |

ASTM D2671B |

Self-extinguish within 30s |

|

Dieletric strength(kV/mm) |

IEC 60243 |

≥15 |

17.5 |

Volume resistivity(Ω.cm) |

IEC 60093 |

≥1X101 4 |

2.5X101 4 |

Property |

Test Method |

Standard |

|---|---|---|

Water Absorption |

ASTM D570 |

<0.2% |

Sofening Point(℃) |

ASTM E28 |

90±5 |

Strength of pearing(PE) |

ASTM D 1000 |

120N/25mm |

Strength of pearing(AL) |

ASTM D 1000 |

80N/25mm |

Adhesive lined heat shrink specifically designed to insulate, seal and protect in-line splices in automotive wire harnesses and electronic assemblies

|

Size |

Expanded |

After Recovery |

Standard Package |

|||

|---|---|---|---|---|---|---|

|

Inch |

mm |

Internal Diameter Min(mm) |

Internal Diameter Max(mm) |

Total Wall Thickness Nom(mm) |

Adhesive Thickness Nom(mm) |

|

|

5/32 |

4 |

4.0 |

0.95 |

1.40±0.30 |

0.60±0.20 |

1.22 OR 25M/Roll |

|

1/4 |

6 |

6.0 |

1.27 |

1.70±0.30 |

0.80±0.20 |

1.22 OR 25M/Roll |

|

5/16 |

8 |

8.0 |

1.65 |

2.00±0.30 |

0.95±0.20 |

1.22 OR 25M/Roll |

|

2/5 |

10 |

10.0 |

2.00 |

2.20±0.40 |

1.10±0.20 |

1.22 OR 25M/Roll |

|

1/ 2 |

12 |

12.0 |

2.41 |

2.45±0.40 |

1.20±0.20 |

1.22 OR 25M/Roll |

|

3/4 |

18 |

18.0 |

4.45 |

2.60±0.40 |

1.34±0.30 |

1.22 OR 25M/Roll |

Property |

Test Method |

Standard |

Typical Performance |

|---|---|---|---|

Tensile Strengtn(MPa) |

ASTM D2671 |

≥10.4 |

11.5 |

Elongation(%) |

ASTM D2671 |

≥300 |

450 |

Tensile Strengtn after aging (MPa) |

UL224 158℃X168hr |

≥7.3 |

8.5 |

Elongation after aging(%) |

UL224 158℃X168hr |

≥200 |

350 |

Dieletric strength(kV/mm) |

IEC 60243 |

≥15 |

17.5 |

Volume resistivity(Ω.cm) |

IEC 60093 |

≥1X101 4 |

2.5X101 4 |

Property |

Test Method |

Standard |

|---|---|---|

Water Absorption |

ASTM D570 |

<0.2% |

Sofening Point(℃) |

ASTM E28 |

90±5 |

Strength of pearing(PE) |

ASTM D 1000 |

120N/25mm |

Strength of pearing(AL) |

ASTM D 1000 |

80N/25mm |

Adhesive Semi-rigid, dual wall heat shrink tubing designed to seal&

environmentally protect splice in the most

Size |

Expanded |

After Recovery |

Standard Package |

|||

|---|---|---|---|---|---|---|

Inch |

mm |

Internal Diameter Min(mm) |

Internal Diameter Max(mm) |

Total Wall Thickness Nom(mm) |

Adhesive Thickness Nom(mm) |

Spool Length M/spool |

2/13 |

4 |

4.0 |

0.95 |

1.40±0.30 |

0.60±0.20 |

200 |

1/4 |

6 |

6.0 |

1.27 |

1.70±0.30 |

0.80±0.20 |

100 |

5/16 |

8 |

8.0 |

1.65 |

2.00±0.30 |

0.95±0.20 |

100 |

|

10 |

10.0 |

2.00 |

2.30±0.40 |

1.10±0.20 |

1.22 OR 25M/Roll |

1/ 2 |

12 |

12.0 |

2.41 |

2.45±0.40 |

1.20±0.20 |

1.22 OR 25M/Roll |

3/4 |

18 |

18.0 |

4.45 |

2.60±0.40 |

1.34±0.30 |

1.22 OR 25M/Roll |

Property |

Test Method |

Standard |

Typical Performance |

|---|---|---|---|

Tensile Strengtn(MPa) |

ASTM D2671 |

≥10.4 |

11.5 |

Elongation(%) |

ASTM D2671 |

≥300 |

450 |

Tensile Strengtn after aging (MPa) |

UL224 158℃X168hr |

≥7.3 |

8.5 |

Elongation after aging(%) |

Ul224 158℃X168hr |

≥200 |

350 |

Dieletric strength(kV/mm) |

IEC 60243 |

≥15 |

17.5 |

Volume resistivity(Ω.cm) |

IEC 60093 |

≥1X101 4 |

2.5X101 4 |

Property |

Test Method |

Standard |

|---|---|---|

Water Absorption |

ASTM D570 |

<0.2% |

Sofening Point(℃) |

ASTM E28 |

90±5 |

Strength of pearing(PE) |

ASTM D 1000 |

120N/25mm |

Strength of pearing(AL) |

ASTM D 1000 |

80N/25mm |

Highly flame retardant, semi-rigid, cross-linked dual wall heat-shrink tubing designed for splice sealing and fuse link protection

|

Size |

Expanded |

After Recovery |

Standard Package |

|||

|---|---|---|---|---|---|---|

|

Inch |

mm |

Internal Diameter Min(mm) |

Internal Diameter Max(mm) |

Total Wall Thickness Nom(mm) |

Adhesive Thickness Nom(mm) |

|

|

2/13 |

4 |

4.0 |

0.95 |

1.40±0.30 |

0.60±0.20 |

1.22 |

|

1/4 |

6 |

6.0 |

1.27 |

1.70±0.30 |

0.80±0.20 |

1.22 |

|

5/16 |

8 |

8.0 |

1.65 |

2.00±0.30 |

0.95±0.20 |

1.22 |

|

|

10 |

10.0 |

2.00 |

2.30±0.40 |

1.10±0.20 |

1.22 |

|

1/ 2 |

12 |

12.0 |

2.41 |

2.45±0.40 |

1.20±0.20 |

1.22 |

|

3/4 |

18 |

18.0 |

4.45 |

2.60±0.40 |

1.34±0.30 |

1.22 |

Property |

Test Method |

Standard |

Typical Performance |

|---|---|---|---|

Tensile Strengtn(MPa) |

ASTM D2671 |

≥10.4 |

11.5 |

Elongation(%) |

ASTM D2671 |

≥ 300 |

450 |

Tensile Strengtn after aging (MPa) |

UL224 158 X168hr |

≥7.3 |

8.5 |

Elongation after aging(%) |

UL224 158 X168hr |

≥200 |

350 |

Dieletric strength(kV/mm) |

IEC 60243 |

≥15 |

17.5 |

Volume resistivity(Ω.cm) |

IEC 60093 |

≥1X101 4 |

2.5X101 4 |

Property |

Test Method |

Standard |

|---|---|---|

Water Absorption |

ASTM D570 |

<0.2% |

Sofening Point(℃) |

ASTM E28 |

90±5 |

Strength of pearing(PE) |

ASTM D 1000 |

120N/25mm |

Strength of pearing(AL) |

ASTM D 1000 |

80N/25mm |

Medium wall adhesive-lined heat Shrink tubing suitable for a variety of low voltage electrical and mechanical application, where lighter weight and greater flexibility are important.

|

Size |

Expanded |

After Recovery |

Standard Package M/pc |

|||

|---|---|---|---|---|---|---|

|

mm |

Internal Diameter mm |

Internal Diameter mm |

Jacket Thickness mm |

Adhesive Thickness mm |

Total Wall Thickness mm |

|

|

10.2/3.0 |

10.2 |

3.0 |

1.40±0.20 |

0.35±0.15 |

1.75±0.30 |

1.22 |

|

16.0/5.0 |

16.0 |

5.0 |

1.50±0.20 |

0.40±0.15 |

1.90±0.30 |

1.22 |

|

19.1/5.6 |

19.1 |

5.6 |

2.00±0.20 |

0.45±0.15 |

2.45±0.40 |

1.22 |

|

25.0/8.0 |

25.0 |

8.0 |

2.00±0.20 |

0.45±0.15 |

2.45±0.40 |

1.22 |

|

28.0/9.0 |

28.0 |

9.0 |

2.00±0.20 |

0.50±0.20 |

2.60±0.40 |

1.22 |

|

35.0/10.2 |

35.0 |

10.2 |

2.20±0.20 |

0.78±0.20 |

2.70±0.40 |

1.22 |

|

38.1/12.0 |

38.1 |

12.0 |

2.20±0.20 |

0.50±0.20 |

2.70±0.40 |

1.22 |

|

43.2/12.7 |

43.2 |

12.7 |

2.20±0.25 |

0.50±0.20 |

2.70±0.40 |

1.22 |

|

52.1/16.0 |

52.1 |

16.0 |

2.30±0.25 |

0.50±0.20 |

2.80±0.45 |

1.22 |

|

55.0/16.0 |

55.0 |

16.0 |

2.30±0.25 |

0.50±0.20 |

2.80±0.45 |

1.22 |

|

63.0/19.0 |

63.0 |

19.0 |

2.50±0.25 |

0.50±0.20 |

3.00±0.45 |

1.22 |

|

75.0/22.0 |

75.0 |

22.0 |

2.60±0.25 |

0.50±0.20 |

3.00±0.45 |

1.22 |

|

85.0/25.0 |

85.0 |

25.0 |

2.80±0.35 |

0.50±0.20 |

3.30±0.45 |

1.22 |

|

95.0/29.0 |

95.0 |

29.0 |

3.10±0.45 |

0.60±0.20 |

3.70±0.50 |

1.22 |

|

115.0/34.0 |

115.0 |

34.0 |

3.10±0.45 |

0.60±0.20 |

3.70±0.50 |

1.22 |

|

140.0/42.0 |

140.0 |

42.0 |

3.10±0.45 |

0.60±0.20 |

3.70±0.50 |

1.22 |

|

160.0/48.0 |

160.0 |

48.0 |

3.10±0.45 |

0.60±0.20 |

3.70±0.50 |

1.22 |

|

180.0/58.0 |

180.0 |

58.0 |

3.10±0.45 |

0.60±0.20 |

3.70±0.50 |

1.22 |

|

200.0/60.0 |

≥200.0 |

≤60.0 |

3.10±0.45 |

0.60±0.20 |

3.70±0.50 |

1.22 |

|

230.0/69.0 |

≥230.0 |

≤69.0 |

3.10±0.45 |

0.60±0.20 |

3.70±0.50 |

1.22 |

Note: Tubing without adhesive is available upon request

Property |

Test Method |

Standard |

Typical Performance |

|---|---|---|---|

Tensile Strengtn(MPa) |

ASTM D2671 |

≥10.4 |

11.5 |

Elongation(%) |

ASTM D2671 |

≥300 |

450 |

Tensile Strengtn after aging (MPa) |

UL224 158℃X168hr |

≥7.3 |

8.5 |

Elongation after aging(%) |

UL224 158℃X168hr |

≥200 |

350 |

Dieletric strength(kV/mm) |

IEC 60243 |

≥15 |

17.5 |

Volume resistivity(Ω.cm) |

IEC 60093 |

≥1X101 4 |

2.5X101 4 |

Property |

Test Method |

Standard |

|---|---|---|

Water Absorption |

ASTM D570 |

<0.2% |

Sofening Point(℃) |

ASTM E28 |

95±5 |

Strength of pearing(PE) |

ASTM D 1000 |

120N/25mm |

Strength of pearing(AL) |

ASTM D 1000 |

80N/25mm |

Medium wall heat shrinkable tubing suitable for a variety of low voltage electrical and mechanical application, where lighter weight and greater flexibility are important

|

Size |

Expanded |

After Recovery |

Standard Package M/pc |

|||

|---|---|---|---|---|---|---|

|

mm |

Internal Diameter mm |

Internal Diameter mm |

Jacket Thickness mm |

Adhesive Thickness mm |

Total Wall Thickness mm |

|

|

6.0/2.0 |

6.0 |

2.0 |

1.40±0.20 |

0.45±0.15 |

1.85±0.30 |

1.22 |

|

8.0/2.0 |

8.0 |

2.0 |

1.40±0.20 |

0.45±0.15 |

1.85±0.30 |

1.22 |

|

10.2/3.0 |

10.2 |

3.0 |

1.40±0.20 |

0.50±0.15 |

1.90±0.30 |

1.22 |

|

12.0/3.0 |

12.0 |

3.0 |

1.40±0.20 |

0.50±0.15 |

1.90±0.30 |

1.22 |

|

16.0/5.0 |

16.0 |

5.0 |

1.50±0.20 |

0.55±0.20 |

2.15±0.35 |

1.22 |

|

19.1/5.6 |

19.1 |

5.6 |

1.80±0.20 |

0.60±0.20 |

2.40±0.40 |

1.22 |

|

22.0/6.0 |

22.0 |

6.0 |

2.00±0.30 |

0.60±0.20 |

2.60±0.40 |

1.22 |

|

25.0/8.0 |

25.0 |

8.0 |

2.00±0.30 |

0.65±0.20 |

2.70±0.40 |

1.22 |

|

28.0/6.0 |

28.0 |

6.0 |

2.40±0.30 |

0.95±0.25 |

3.30±0.45 |

1.22 |

|

33.0/8.0 |

33.0 |

8.0 |

2.50±0.30 |

0.80±0.25 |

3.30±0.45 |

1.22 |

|

38.1/12.0 |

38.1 |

12.0 |

2.40±0.30 |

0.80±0.25 |

3.30±0.45 |

1.22 |

|

43.2/12.7 |

43.2 |

12.7 |

2.40±0.30 |

0.80±0.25 |

3.30±0.45 |

1.22 |

|

55.0/16.0 |

55.0 |

16.0 |

2.40±0.30 |

0.80±0.25 |

3.30±0.45 |

1.22 |

|

65.0/19.0 |

65.0 |

19.0 |

2.50±0.30 |

0.80±0.25 |

3.30±0.45 |

1.22 |

|

75.0/22.0 |

75.0 |

22.0 |

2.90±0.30 |

0.80±0.25 |

3.70±0.50 |

1.22 |

|

85.0/25.0 |

85.0 |

25.0 |

2.90±0.30 |

0.80±0.25 |

3.70±0.50 |

1.22 |

|

95.0/30.0 |

95.0 |

30.0 |

3.00±0.30 |

0.80±0.25 |

3.70±0.50 |

1.22 |

|

115.0/34.0 |

115.0 |

34.0 |

3.00±0.30 |

0.80±0.25 |

3.70±0.50 |

1.22 |

|

140.0/42.0 |

140.0 |

42.0 |

3.00±0.30 |

0.80±0.25 |

3.70±0.50 |

1.22 |

|

160.0/50.0 |

160.0 |

50.0 |

3.10±0.30 |

0.80±0.25 |

3.70±0.50 |

1.00 |

|

180.0/65.0 |

180.0 |

65.0 |

3.10±0.30 |

0.80±0.25 |

3.70±0.50 |

1.00 |

|

200.0/69.0 |

200.0 |

69.0 |

3.10±0.30 |

0.80±0.25 |

3.70±0.50 |

1.00 |

|

230.0/78.0 |

230.0 |

78.0 |

3.10±0.30 |

0.80±0.25 |

3.70±0.50 |

1.00 |

Note: Tubing without adhesive is available upon request

Property |

Test Method |

Standard |

Typical Performance |

|---|---|---|---|

Tensile Strengtn(MPa) |

ASTM D2671 |

≥14 |

15 |

Elongation(%) |

ASTM D2671 |

≥400 |

450 |

Tensile Strengtn after aging (MPa) |

UL224 158℃X168hr |

≥12 |

12.5 |

Elongation after aging(%) |

Ul224 158℃X168hr |

≥300 |

350 |

Dieletric strength(kV/mm) |

IEC 60243 |

≥15 |

17.5 |

Volume resistivity(Ω.cm) |

IEC 60093 |

≥1X101 4 |

2.5X101 4 |

Property |

Test Method |

Standard |

|---|---|---|

Water Absorption |

ASTM D570 |

<0.2% |

Sofening Point(℃) |

ASTM E28 |

95±5 |

Strength of pearing(PE) |

ASTM D 1000 |

120N/25mm |

Strength of pearing(AL) |

ASTM D 1000 |

80N/25mm |

Heat shrinkable tubing and adhesive liner combination that established the CATV industry standard for splice and connector protection

|

Size |

Expanded |

After Recovery |

Standard Package M/pc |

|||

|---|---|---|---|---|---|---|

|

mm |

Internal Diameter mm |

Internal Diameter mm |

Jacket Thickness mm |

Adhesive Thickness mm |

Total Wall Thickness mm |

|

|

10.2/3.8 |

10.2 |

3.8 |

1.40±0.20 |

0.50±0.10 |

1.90±0.25 |

1.22 |

|

19.0/5.6 |

19.0 |

5.6 |

1.80±0.20 |

0.60±0.15 |

2.40±0.30 |

1.22 |

|

28.0/6.0 |

28.0 |

6.0 |

2.40±0.30 |

0.95±0.20 |

3.30±0.35 |

1.22 |

|

33.0/8.0 |

33.0 |

8.0 |

2.50±0.30 |

0.80±0.15 |

3.30±0.35 |

1.22 |

|

38.1/12.0 |

38.1 |

12.0 |

2.40±0.30 |

0.80±0.15 |

3.30±0.35 |

1.22 |

|

43.2/12.7 |

43.2 |

12.7 |

2.40±0.30 |

0.80±0.15 |

3.30±0.35 |

1.22 |

|

55.0/16.0 |

55.0 |

16.0 |

2.40±0.30 |

0.80±0.15 |

3.30±0.35 |

1.22 |

|

70.0/25.4 |

70.0 |

25.4 |

2.80±0.30 |

0.60±0.15 |

3.40±0.40 |

1.22 |

Property |

Test Method |

Standard |

Typical Performance |

|---|---|---|---|

Tensile Strengtn(MPa) |

ASTM D2671 |

≥10.4 |

11.5 |

Elongation(%) |

ASTM D2671 |

≥300 |

450 |

Tensile Strengtn after aging (MPa) |

UL224 158 X168hr |

≥7.3 |

8.5 |

Elongation after aging(%) |

UL224 158 X168hr |

≥200 |

350 |

Dieletric strength(kV/mm) |

IEC 60243 |

≥15 |

17.5 |

Volume resistivity(Ω.cm) |

IEC 60093 |

≥1X101 4 |

2.5X101 4 |

Property |

Test Method |

Standard |

|---|---|---|

Water Absorption |

ASTM D570 |

<0.2% |

Sofening Point(℃) |

ASTM E28 |

85 |

Strength of pearing(PE) |

ASTM D 1000 |

120N/25mm |

Strength of pearing(AL) |

ASTM D 1000 |

80N/25mm |

Adhesive-lined heavy wall heat shrink tubing insulates and protects electrical splice and terminations where maximum flame retardancy and exceptional insulating and sealing characteristics are required.

Size |

Expanded |

After Recovery |

Standard Package M/pc |

|||

|---|---|---|---|---|---|---|

mm |

Internal Diameter mm |

Internal Diameter mm |

Jacket Thickness mm |

Adhesive Thickness mm |

Total Wall Thickness mm |

|

9.0/3.0 |

9.0 |

3.0 |

2.00±0.35 |

0.45±0.20 |

2.45±0.35 |

1.22 |

13.0/4.0 |

13.0 |

4.0 |

2.30±0.35 |

0.45±0.20 |

2.80±0.35 |

1.22 |

20.0/6.0 |

20.0 |

6.0 |

2.30±0.35 |

0.60±0.20 |

2.90±0.35 |

1.22 |

28.0/9.0 |

28.0 |

9.0 |

2.30±0.35 |

0.70±0.20 |

3.00±0.40 |

1.22 |

33.0/10.2 |

33.0 |

10.2 |

2.80±0.35 |

0.70±0.20 |

3.60±0.40 |

1.22 |

38.1/12.0 |

38.1 |

12.0 |

3.10±0.35 |

0.70±0.20 |

3.85±0.50 |

1.22 |

43.2/12.7 |

43.2 |

12.0 |

3.50±0.35 |

0.70±0.20 |

4.20±0.50 |

1.22 |

51.0/16.0 |

55.0 |

16.0 |

3.85±0.40 |

0.70±0.20 |

4.50±0.50 |

1.22 |

70.0/21.0 |

75.0 |

22.0 |

3.65±0.40 |

0.70±0.20 |

4.40±0.50 |

1.22 |

85.0/25.0 |

85.0 |

25.0 |

3.65±0.40 |

0.70±0.20 |

4.40±0.50 |

1.22 |

105.0/30.0 |

105.0 |

30.0 |

3.85±0.40 |

0.70±0.20 |

4.50±0.50 |

1.22 |

120.0/36.0 |

120.0 |

36.0 |

3.85±0.40 |

0.70±0.20 |

4.50±0.50 |

1.22 |

130.0/36.0 |

130.0 |

36.0 |

3.85±0.40 |

0.70±0.20 |

4.50±0.50 |

1.22 |

140.0/42.0 |

140.0 |

42.0 |

3.85±0.40 |

0.70±0.20 |

4.50±0.50 |

1.22 |

Note: Tubing without adhesive is available upon request

Property |

Test Method |

Standard |

Typical Performance |

|---|---|---|---|

Tensile Strengtn(MPa) |

ASTM D2671 |

≥10.4 |

11.5 |

Elongation(%) |

ASTM D2671 |

≥300 |

450 |

Tensile Strengtn after aging (MPa) |

UL224 158℃X168hr |

≥7.3 |

8.5 |

Elongation after aging(%) |

Ul224 158℃X168hr |

≥200 |

350 |

Dieletric strength(kV/mm) |

IEC 60243 |

≥15 |

17.5 |

Volume resistivity(Ω.cm) |

IEC 60093 |

≥1X101 4 |

2.5X101 4 |

Property |

Test Method |

Standard |

|---|---|---|

Water Absorption |

ASTM D570 |

<0.2% |

Sofening Point(℃) |

ASTM E28 |

95±5 |

Strength of pearing(PE) |

ASTM D 1000 |

120N/25mm |

Strength of pearing(AL) |

ASTM D 1000 |

80N/25mm |

Heavy wall adhesive-lined heat shrink tubing provides maximum reliability for insulating and protecting cable joints and terminations.

Size |

Expanded |

After Recovery |

Standard Package M/pc |

|||

|---|---|---|---|---|---|---|

mm |

Internal Diameter mm |

Internal Diameter mm |

Jacket Thickness mm |

Adhesive Thickness mm |

Total Wall Thickness mm |

|

8.0/2.0 |

8.0 |

2.0 |

1.80±0.30 |

0.55±0.20 |

2.35±0.35 |

1.22 |

9.0/3.0 |

9.0 |

3.0 |

2.00±0.30 |

0.55±0.20 |

2.55±0.40 |

1.22 |

13.0/4.0 |

13.0 |

4.0 |

2.30±0.30 |

0.55±0.20 |

2.85±0.40 |

1.22 |

16.0/5.0 |

16.0 |

5.0 |

2.30±0.30 |

0.60±0.20 |

2.90±0.50 |

1.22 |

22.0/6.0 |

22.0 |

6.0 |

2.50±0.40 |

0.60±0.25 |

3.10±0.50 |

1.22 |

28.0/6.0 |

28.0 |

6.0 |

2.70±0.40 |

0.70±0.25 |

3.40±0.50 |

1.22 |

33.0/8.0 |

33.0 |

8.0 |

2.80±0.40 |

0.80±0.25 |

3.60±0.60 |

1.22 |

38.1/12.0 |

38.1 |

12.0 |

3.10±0.50 |

0.80±0.25 |

3.90±0.60 |

1.22 |

43.2/12.0 |

43.2 |

12.0 |

3.50±0.50 |

0.80±0.25 |

4.30±0.70 |

1.22 |

55.0/16.0 |

55.0 |

16.0 |

3.60±0.50 |

0.80±0.25 |

4.40±0.70 |

1.22 |

65.0/19.0 |

65.0 |

19.0 |

3.60±0.50 |

0.80±0.25 |

4.40±0.70 |

1.22 |

75.0/22.0 |

75.0 |

22.0 |

3.60±0.50 |

0.80±0.25 |

4.40±0.70 |

1.22 |

85.0/25.0 |

85.0 |

25.0 |

3.60±0.50 |

0.80±0.25 |

4.40±0.70 |

1.22 |

95.0/30.0 |

95.0 |

30.0 |

3.60±0.50 |

0.80±0.25 |

4.40±0.70 |

1.22 |

105.0/30.0 |

105.0 |

30.0 |

3.80±0.60 |

0.80±0.25 |

4.60±0.70 |

1.22 |

120.0/39.0 |

120.0 |

39.0 |

3.80±0.60 |

0.80±0.25 |

4.60±0.70 |

1.22 |

130.0/40.0 |

130.0 |

40.0 |

3.80±0.60 |

0.80±0.25 |

4.60±0.70 |

1.22 |

140.0/42.0 |

140.0 |

42.0 |

3.80±0.60 |

0.80±0.25 |

4.60±0.70 |

1.22 |

160.0/50.0 |

160.0 |

50.0 |

3.80±0.60 |

0.80±0.25 |

4.60±0.70 |

1.00 |

180.0/60.0 |

180.0 |

60.0 |

3.80±0.60 |

0.80±0.25 |

4.60±0.70 |

1.00 |

200.0/69.0 |

200.0 |

69.0 |

3.80±0.60 |

0.80±0.25 |

4.60±0.70 |

1.00 |

Note: Tubing without adhesive is available upon request

Property |

Test Method |

Standard |

Typical Performance |

|---|---|---|---|

Tensile Strengtn(MPa) |

ASTM D2671 |

≥14 |

15 |

Elongation(%) |

ASTM D2671 |

≥400 |

450 |

Tensile Strengtn after aging (MPa) |

UL224 158℃X168hr |

≥12 |

12.5 |

Elongation after aging(%) |

Ul224 158℃X168hr |

≥300 |

350 |

Dieletric strength(kV/mm) |

IEC 60243 |

≥15 |

17.5 |

Volume resistivity(Ω.cm) |

IEC 60093 |

≥1X101 4 |

2.5X101 4 |

Property |

Test Method |

Standard |

|---|---|---|

Water Absorption |

ASTM D570 |

<0.2% |

Sofening Point(℃) |

ASTM E28 |

95±5 |

Strength of pearing(PE) |

ASTM D 1000 |

120N/25mm |

Strength of pearing(AL) |

ASTM D 1000 |

80N/25mm |