Description: AMS marker sleeves are designed to meet the wire and cable permanent marking needs. It is made of durable and flame retardant heat shrinkable polyolefin, and radiation cross-linked by high energy electronic beam.

Standard: AMS meets AMS-DTL-23053/5 Class 1&3, SAE-AS 81531, MIL-STD-202F/Method 215J, UL224, VW-1, RoHS.

| Material | The sleeving shall be fabricated from irradiated, thermally stabilized and flame retarded modified polyolefin compound |

| Application range | Military industry; Aerospace & defense; Marine; |

| Operating temperature range | -55~+135℃ |

| Minimum recovery temperature | +135℃ |

| Maximum storage temperature | +50℃ |

| Shrink ratio | 2:1, 3:1 |

| Color | White, Yellow, other color is available if ordered |

| Printing mode | Single sided printing and Double sided printing formats available |

| Supplied mode | Either Continuous type or Ladder format type is available |

| Recommended Printers | Either Thermal transfer printer or Laser printer is OK. |

| Recommended Ribbons | WO-80500BK resin ribbon, Black |

|

Part Number |

As Supplied (mm) |

After Recovery(mm) |

|||

|---|---|---|---|---|---|

|

ID (D)

|

Flatten Width (W) |

Double Wall Thickness |

ID (d) |

Single Wall Thickness |

|

|

|

3.7±0.3 |

2.00±0.20 |

0.45±0.06 |

≤0.79 |

0.48±0.10 |

|

|

2.79±0.20 |

5.0±0.3 |

0.48±0.10 |

≤1.18 |

0.49±0.06 |

|

|

3.64±0.23 |

6.3±0.4 |

0.48±0.10 |

≤1.59 |

0.51±0.06 |

|

|

5.26±0.25 |

8.9±0.4 |

0.49±0.10 |

≤2.36 |

0.54±0.06 |

|

|

6.92±0.28 |

11.5±0.4 |

0.50±0.10 |

≤3.18 |

0.56±0.06 |

|

|

10.2±0.32 |

16.7±0.5 |

0.51±0.11 |

≤4.75 |

0.59±0.06 |

|

|

13.5±0.36 |

21.8±0.6 |

0.52±0.11 |

≤6.35 |

0.60±0.07 |

|

|

20.1±0.40 |

32.2±0.6 |

0.53±0.11 |

≤9.53 |

0.62±0.07 |

|

|

26.7±0.45 |

42.5±0.7 |

0.55±0.12 |

≤12.7 |

0.63±0.07 |

|

|

39.8±0.51 |

63.2±0.8 |

0.57±0.12 |

≤19.1 |

0.64±0.07 |

|

|

53.0±0.56 |

83.9±0.9 |

0.58±0.13 |

≤25.4 |

0.64±0.08 |

|

|

79.4±0.56 |

125.3±1.0 |

0.59±0.13 |

≤38.1 |

0.64±0.09 |

|

Part Number |

As Supplied (mm) |

After Recovery(mm) |

|||

|---|---|---|---|---|---|

|

ID (D)

|

Flatten Width (W) |

Double Wall Thickness |

ID (d) |

Single Wall Thickness |

|

|

|

3.7±0.3 |

≤0.53 |

0.52±0.06 |

||

|

2.00±0.20 |

0.47±0.10 |

||||

|

|

2.79±0.20 |

5.0±0.3 |

0.47±0.10 |

≤0.79 |

0.57±0.06 |

|

|

3.64±0.23 |

6.3±0.4 |

0.48±0.10 |

≤1.06 |

0.61±0.06 |

|

|

5.26±0.25 |

8.9±0.4 |

0.49±0.10 |

≤1.59 |

0.67±0.06 |

|

|

6.92±0.28 |

11.5±0.4 |

0.50±0.10 |

≤2.13 |

0.71±0.06 |

|

|

10.2±0.32 |

16.7±0.5 |

0.52±0.11 |

≤3.18 |

0.77±0.06 |

|

|

13.5±0.36 |

21.8±0.6 |

0.53±0.11 |

≤4.23 |

0.80±0.07 |

|

|

20.1±0.40 |

32.2±0.6 |

0.55±0.11 |

≤6.35 |

0.84±0.07 |

|

|

26.7±0.45 |

42.5±0.7 |

0.565±0.12 |

≤8.47 |

0.86±0.07 |

|

|

39.8±0.51 |

63.2±0.8 |

0.57±0.12 |

≤12.9 |

0.89±0.07 |

|

|

53.0±0.56 |

83.9±0.9 |

0.57±0.12 |

≤17.2 |

0.90±0.08 |

|

|

79.4±0.56 |

125.3±1.0 |

0.57±0.13 |

≤25.8 |

0.92±0.09 |

|

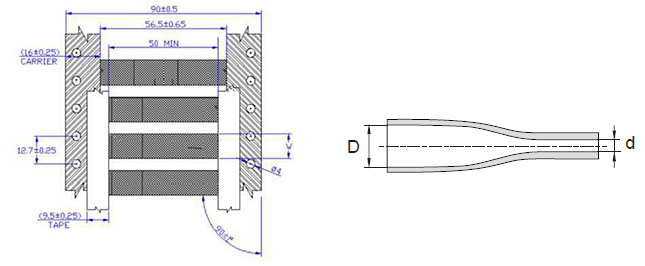

Ordering Size (AMS-M-2X/3X) |

Ladder Format Type |

Continuous Type |

|

|---|---|---|---|

|

|

|

|

|

|

Φ1.6 |

2500 |

50 |

25 |

|

Φ2.4 |

2500 |

50 |

25 |

|

Φ3.2 |

2000 |

100 |

25 |

|

Φ4.8 |

2000 |

100 |

25 |

|

Φ6.4 |

2000 |

100 |

25 |

|

Φ9.5 |

1000 |

100 |

25 |

|

Φ12.7 |

1000 |

100 |

25 |

|

Φ19 |

500 |

100 |

25 |

|

Φ25 |

500 |

100 |

25 |

|

Φ38 |

500 |

50 |

25 |

|

Φ51 |

250 |

50 |

25 |

|

Φ76 |

250 |

50 |

25 |

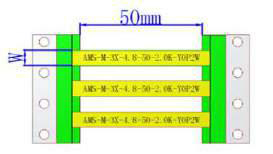

AMS-M-3X-4.8-50-2.0K-Y 0 P2 W

Package: W for WOLABLE painting package.O for OEM package

Printing: P0/P1/P2 for printing/single-side printing/ double-side printing

Dash line: 0/1/2/3......for not need/one line/two-line/three-line......

Color: Y for yellow, W for white and ten colors are available

Standard pack: 2.5K/2K/1.5K/1K/0.5K/0.25K/for 2500/....../500 and 250 pieces

Sleeve length: nominal length is 50mm(the total length is 56.5mm)

Expanded ID: as supplid,nominal inside diameter

Expansion ratio: 2X/3X refers to 2:1or 3:1

Standard wall thickness

Product family: AMS refer to AMS-DTL-23053/5

Description: HMS marker sleeves are used to identify wires and cables where exposure to organic fluids, especially diesel oils, for long period of high of temperatures.

Standard: HMS meets AMS-DTL-23053/6 Class 1, NF F 00608 Categories A&H, SAE-AS 81531, MIL-STD-202F/Method 215J, RoHS

| Material | The sleeving shall be fabricated from irradiated, thermally stabilized and flame retarded modified polyolefin compound |

| Application range | Military industry; Aerospace & defense; Marine; |

| Operating temperature range | -55~+135℃ |

| Minimum recovery temperature | +135℃ |

| Maximum storage temperature | +50℃ |

| Shrink ratio | 3:1 |

| Color | White, Yellow, other color is available if ordered |

| Printing mode | Single sided printing and Double sided printing formats available |

| Supplied mode | Either Continuous type or Ladder format type is available |

| Recommended Printers | Either Thermal transfer printer or Laser printer is OK. |

| Recommended Ribbons | N85 resin ribbon, Black, 100mm(width)*300m(length) |

Part Number |

As Supplied (mm) |

After Recovery (mm) |

|||

|---|---|---|---|---|---|

ID (D) |

Flatten Width (W) |

Double Wall Thickness |

ID (d) |

Single Wall Thickness |

|

2.79±0.20 |

5.0±0.3 |

0.47±0.10 |

≤0.79 |

0.57±0.06 |

|

3.64±0.23 |

6.3±0.4 |

0.48±0.10 |

≤1.06 |

0.61±0.06 |

|

5.26±0.25 |

8.9±0.4 |

0.49±0.10 |

≤1.59 |

0.67±0.06 |

|

6.92±0.28 |

11.5±0.4 |

0.50±0.10 |

≤2.13 |

0.71±0.06 |

|

10.2±0.32 |

16.7±0.5 |

0.52±0.11 |

≤3.18 |

0.77±0.06 |

|

13.5±0.36 |

21.8±0.6 |

0.53±0.11 |

≤4.23 |

0.80±0.07 |

|

20.1±0.40 |

32.2±0.6 |

0.55±0.11 |

≤6.35 |

0.84±0.07 |

|

26.7±0.45 |

42.5±0.7 |

0.56±0.12 |

≤8.47 |

0.86±0.07 |

|

39.8±0.51 |

63.2±0.8 |

0.57±0.12 |

≤12.9 |

0.89±0.07 |

|

Ordering Size (HMS-M-3X) |

Ladder Format Type |

Continuous Type |

|

|---|---|---|---|

A&B-Small Box Packing (PCS/Box) |

A-Paper reel Packing (m/reel) |

B-Plastic reel Packing (m/reel) |

|

Φ2.4 |

2500 |

50 |

25 |

Φ3.2 |

2000 |

100 |

25 |

Φ4.8 |

2000 |

100 |

25 |

Φ6.4 |

2000 |

100 |

25 |

Φ9.5 |

1000 |

100 |

25 |

Φ12.7 |

1000 |

100 |

25 |

Φ19 |

500 |

100 |

25 |

Φ25 |

500 |

100 |

25 |

Φ38 |

500 |

50 |

25 |

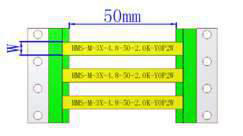

HMS-M-3X-4.8-50-2.0K-Y 0 P2 W

Package:W for WOLABLE painting package.O for OEM package

Printing:P0/P1/P2 for printing/single-side printing/ double-side printing

Dash line:0/1/2/3......for not need/one line/two-line/three-line......

Color:Y for yellow, W for white and ten colors are available

Standard pack:2.5K/2K/1.5K/1K/0.5K/0.25K/for 2500/....../500 and 250 pieces

Sleeve length:nominal length is 50mm(the total length is 56.5mm)

Expanded ID:as supplid,nominal inside diameter

Expansion ratio:3X refers to 3:1

Standard wall thickness

Product family:HMS refer to AMS-DTL-23053/6

|

Color code |

BL |

Br |

R |

Or |

Y |

G |

Blu |

V |

Gr |

W |

|---|---|---|---|---|---|---|---|---|---|---|

|

Color |

Black |

Brown |

Red |

Orange |

Yellow |

Green |

Blue |

Violet |

Grey |

White |

Note: Yellow and white are standard, other color is available if ordered.

Description: HNF marker sleeve is a flattened, heat-shrinkable tubing designed for wire and cable harness identification. It can also be used for applications where limited fire hazard characteristics are necessary. The zero halogen material coupled with low smoke and low toxic fume emissions make this product perfectly used in enclosed spaces such as mass transit, marine and industrial installations.

Standard: NF F16-101, DIN5510-2, BS 6853, EN45545-2, SAE-AS 81531, MIL-STD-202F/Method 215J, RoHS ,FPA130

| Material | The sleeving shall be fabricated from irradiated, thermally stabilized and flame retarded modified polyolefin compound containing no halogens or cadmium in the formulation. |

| Application range | Industrial environment ; Rail & mass transit; Aerospace & defense; Marine; |

| Operating temperature range | -55~+125 |

| Minimum recovery temperature | +115 |

| Maximum storage temperature | +40 |

| Shrink ratio | 2:1 |

| Color | White, Yellow, other color is available if ordered |

| Printing mode | Single sided printing and Double sided printing formats available |

| Supplied mode | Either Continuous type or Ladder format type is available |

| Recommended Printers | Thermal transfer printer |

| Recommended Ribbons | N85 resin ribbon, Black, 100mm(width)*300m(length) |

Part Number |

As Supplied (mm) |

After Recovery (mm) |

|||

|---|---|---|---|---|---|

ID (D) |

Flatten Width (W) |

Double Wall Thickness |

ID (d) |

Single Wall Thickness |

|

2.79±0.20 |

5.0±0.3 |

0.48±0.10 |

≤1.18 |

0.49±0.06 |

|

3.64±0.23 |

6.3±0.4 |

0.48±0.10 |

≤1.59 |

0.51±0.06 |

|

5.26±0.25 |

8.9±0.4 |

0.49±0.10 |

≤2.36 |

0.54±0.06 |

|

6.92±0.28 |

11.5±0.4 |

0.50±0.10 |

≤3.18 |

0.56±0.06 |

|

10.2±0.32 |

16.7±0.5 |

0.51±0.11 |

≤4.75 |

0.59±0.06 |

|

13.5±0.36 |

21.8±0.6 |

0.52±0.11 |

≤6.35 |

0.60±0.07 |

|

20.1±0.40 |

32.2±0.6 |

0.53±0.11 |

≤9.53 |

0.62±0.07 |

|

26.7±0.45 |

42.5±0.7 |

0.55±0.12 |

≤12.7 |

0.63±0.07 |

|

39.8±0.51 |

63.2±0.8 |

0.57±0.12 |

≤19.1 |

0.64±0.07 |

|

Ordering Size (HNF-M-2X) |

Ladder Format Type |

Continuous Type |

|

|---|---|---|---|

Φ2.4 |

2500 |

50 |

25 |

Φ3.2 |

2000 |

100 |

25 |

Φ4.8 |

2000 |

100 |

25 |

Φ6.4 |

2000 |

100 |

25 |

Φ9.5 |

1000 |

100 |

25 |

Φ12.7 |

1000 |

100 |

25 |

Φ19 |

500 |

100 |

25 |

Φ25 |

500 |

100 |

25 |

Φ38 |

500 |

50 |

25 |

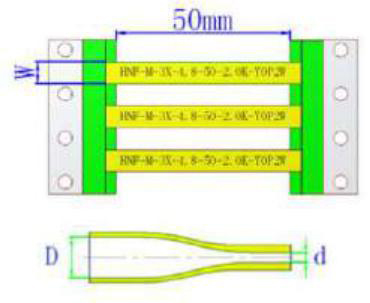

HNF-M-3X-4.8-50-2.0K-Y 0 P2 W

Package:W for WOLABLE painting package.O for OEM package

Printing:P0/P1/P2 for printing/single-side printing/ double-side printing

Dash line:0/1/2/3......for not need/one line/two-line/three-line......

Color:Y for yellow, W for white and ten colors are available

Standard pack:2.5K/2K/1.5K/1K/0.5K/0.25K/for 2500/....../500 and 250 pieces

Sleeve length:nominal length is 50mm(the total length is 56.5mm)

Expanded ID:as supplid,nominal inside diameter

Expansion ratio:2X refers to 2:1

Standard wall thickness

Product family:HNF

|

Color code |

BL |

Br |

R |

Or |

Y |

G |

Blu |

V |

Gr |

W |

|---|---|---|---|---|---|---|---|---|---|---|

|

Color |

Black |

Brown |

Red |

Orange |

Yellow |

Green |

Blue |

Violet |

Grey |

White |

Note:Yellow and white are standard, other color is available if ordered.

Description: PSFR marker sleeve is flattened, heat-shrinkable tubing designed for wire and cable identification in high temperature applications or where extreme resistance to fuels, lubricants and cleaning solvents is required. When PSFR is printed with Woer recommended printers and ink ribbon, the marks remain legible, durable, even when exposed to abrasion, aggressive cleaning solvents, and industrial fluids.

Standard: AMS-DTL-23053/18, SAE-AS 81531, MIL-STD-202F/Method 215J, UL224,RoHS

| Material | The sleeving shall be fabricated from irradiated, thermally stabilized and flame retarded modified PVDF |

| Application range | Aerospace, defense and mass transit industries. |

| Operating temperature range | -55~+225 |

| Minimum recovery temperature | +150 |

| Maximum storage temperature | +50 |

| Shrink ratio | 2:1 |

| Color | White, Yellow, other color is available if ordered |

| Printing mode | Single sided printing and Double sided printing formats available |

| Supplied mode | Either Continuous type or Ladder format type is available |

| Recommended Printers | Thermal transfer printer |

| Recommended Ribbons | N95 resin ribbon, Black, 100mm(width)*300m(length) |

Part Number |

As Supplied (mm) |

After Recovery(mm) |

|

|---|---|---|---|

ID (D) |

ID (d) |

Single Wall Thickness |

|

2.4 |

1.2 |

0.25±0.05 |

|

3.2 |

1.6 |

0.25±0.05 |

|

4.8 |

2.4 |

0.25±0.05 |

|

6.4 |

3.2 |

0.30±0.08 |

|

9.5 |

4.8 |

0.30±0.08 |

|

12.7 |

6.4 |

0.30±0.08 |

|

19.1 |

9.5 |

0.43±0.08 |

|

25.4 |

12.7 |

0.48±0.08 |

|

38.1 |

19.1 |

0.60±0.10 |

|

Ordering Size (PSFR-M-2X) |

Ladder Format Type |

Continuous Type |

|---|---|---|

Small Box Packing (PCS/Box) |

Paper reel Packing (m/reel) |

|

Φ2.4 |

2500 |

50 |

Φ3.2 |

2000 |

100 |

Φ4.8 |

2000 |

100 |

Φ6.4 |

2000 |

100 |

Φ9.5 |

1000 |

100 |

Φ12.7 |

1000 |

100 |

Φ19 |

500 |

100 |

Φ25 |

500 |

100 |

Φ38 |

500 |

50 |

PSFR-M-2X-4.8-50-2.0K-Y 0 P2 W

Package:W for WOLABLE painting package.O for OEM package

Printing:PO/P1/P2 for printing/single-side printing/ double-side printing.

Dash line:0/1/2/3......for not need/one line/two-line/three-line......

Color:Y for yellow, W for white and ten colors are available

Standard pack:2.5K/2K/1.5K/1K/0.5K/0.25K/for 2500/....../500 and 250 pieces

Sleeve length:nominal length is 50mm(the total length is 56.5mm)

Expanded ID:as supplid,nominal inside diameter

Expansion ratio:2X refers to 2:1

Standard wall thickness

Product family:PVDF

|

Color code |

BL |

Br |

R |

Or |

Y |

G |

Blu |

V |

Gr |

W |

|---|---|---|---|---|---|---|---|---|---|---|

|

Color |

Black |

Brown |

Red |

Orange |

Yellow |

Green |

Blue |

Violet |

Grey |

White |

Note:Yellow and white are standard, other color is available if ordered.

Description: The PUR cable markers are made of a thermoplastic polyurethane material, which is a halogen free, flame retardant, hydrolysis and micro organism resistant material. The raw material fulfills UL94-V0. For identification of cables and wires, the markers are supplied on rolls for thermal transfer print.

Use: Markers can be easily removed from the carrier, and applied to cables and wire bundles using cable dies. Thermal transfer printer and WO-80500BK ribbon are recommended for meeting printing performance requirements of SAE AS 81531 and MIL-STD-202F.

|

Order Code |

Color |

Pack size (pcs/coil) |

Marker high (mm) |

Marker length (mm) |

|---|---|---|---|---|

|

|

White |

1000 |

10 |

60 |

|

|

White |

1000 |

15 |

75 |

|

|

White |

500 |

25 |

75 |

|

|

Black |

1000 |

10 |

60 |

|

|

Black |

1000 |

15 |

75 |

|

|

Black |

500 |

25 |

75 |

|

|

Yellow |

1000 |

10 |

60 |

|

|

Yellow |

1000 |

15 |

75 |

|

|

Yellow |

500 |

25 |

75 |

|

|

Red |

1000 |

10 |

60 |

|

|

Red |

1000 |

15 |

75 |

|

|

Red |

500 |

25 |

75 |

|

Properties |

Test Method |

Typical value |

|---|---|---|

|

Hardness |

DIN 53505 |

58 Shore D |

|

Density |

DIN 53475 |

1.27g/cm3 |

|

Tensile strength |

DIN 53504 |

30MPa |

|

Ultimate elongation |

DIN 53504 |

400% |

|

Stress at 20% elongation |

DIN 53504 |

13MPa |

|

Stress at 100% elongation |

DIN 53504 |

19MPa |

|

Stress at 300% elongation |

DIN 53504 |

33MPa |

|

Tear Strength |

DIN 53515 |

110N/mm |

|

Abrasion Loss |

DIN 53516 |

30 mm3 |

|

Compression set at room temperature |

DIN EN ISO 815 |

30% |

|

Compression set at 70°C |

DIN EN ISO 815 |

45% |

|

Notched impact strength (Charpy) +23°C |

DIN EN ISO 179 |

50 kj/m2 |

Description: RSFR marker sleeve is a flattened, heat-shrinkable tubing intended for wire and cable harness identification. It can also be used for applications where limited fire hazard characteristics are necessary. When RSFR is printed with Woer recommended printers and ink ribbons, the marks remain legible, durable, even when exposed to abrasion, aggressive cleaning solvents, and industrial fluids.

Standard: SAE-AS 81531, MIL-STD-202F/Method 215J, UL224,RoHS

| Material | The sleeving shall be fabricated from irradiated, thermally stabilized and flame retarded modified polyolefin compound containing no halogens or cadmium in the formulation. |

| Application range | commercial Industrial environment |

| Operating temperature range | -55~+125 |

| Minimum recovery temperature | +125 |

| Maximum storage temperature | +50 |

| Shrink ratio | 2:1, 3:1 |

| Color | White, Yellow, other color is available if ordered |

| Printing mode | Single sided printing and Double sided printing formats available |

| Supplied mode | Either Continuous type or Ladder format type is available |

| Recommended Printers | Thermal transfer printer |

| Recommended Ribbons | N85 resin ribbon, Black, 100mm(width)*300m(length) |

Part Number |

As Supplied (mm) |

After Recovery(mm) |

|||

|---|---|---|---|---|---|

ID (D) |

Flatten Width (W) |

Double Wall Thickness |

ID (d) |

Single Wall Thickness |

|

2.79±0.20 |

5.0±0.3 |

0.48±0.10 |

≤1.18 |

0.49±0.06 |

|

3.64±0.23 |

6.3±0.4 |

0.48±0.10 |

≤1.59 |

0.51±0.06 |

|

5.26±0.25 |

8.9±0.4 |

0.49±0.10 |

≤2.36 |

0.54±0.06 |

|

6.92±0.28 |

11.5±0.4 |

0.50±0.10 |

≤3.18 |

0.56±0.06 |

|

10.2±0.32 |

16.7±0.5 |

0.51±0.11 |

≤4.75 |

0.59±0.06 |

|

13.5±0.36 |

21.8±0.6 |

0.52±0.11 |

≤6.35 |

0.60±0.07 |

|

20.1±0.40 |

32.2±0.6 |

0.53±0.11 |

≤9.53 |

0.62±0.07 |

|

26.7±0.45 |

42.5±0.7 |

0.55±0.12 |

≤12.7 |

0.63±0.07 |

|

39.8±0.51 |

63.2±0.8 |

0.57±0.12 |

≤19.1 |

0.64±0.07 |

|

53.0±0.56 |

83.9±0.9 |

0.58±0.13 |

≤25.4 |

0.64±0.08 |

|

Part Number |

As Supplied (mm) |

After Recovery(mm) |

|||

|---|---|---|---|---|---|

ID (D) |

Flatten Width (W) |

Double Wall Thickness |

ID (d) |

Single Wall Thickness |

|

2.79±0.20 |

5.0±0.3 |

0.47±0.10 |

≤0.79 |

0.57±0.06 |

|

3.64±0.23 |

6.3±0.4 |

0.48±0.10 |

≤1.06 |

0.61±0.06 |

|

5.26±0.25 |

8.9±0.4 |

0.49±0.10 |

≤1.59 |

0.67±0.06 |

|

6.92±0.28 |

11.5±0.4 |

0.50±0.10 |

≤2.13 |

0.71±0.06 |

|

10.2±0.32 |

16.7±0.5 |

0.52±0.11 |

≤3.18 |

0.77±0.06 |

|

13.5±0.36 |

21.8±0.6 |

0.53±0.11 |

≤4.23 |

0.80±0.07 |

|

20.1±0.40 |

32.2±0.6 |

0.55±0.11 |

≤6.35 |

0.84±0.07 |

|

26.7±0.45 |

42.5±0.7 |

0.56±0.12 |

≤8.47 |

0.86±0.07 |

|

39.8±0.51 |

63.2±0.8 |

0.57±0.12 |

≤12.9 |

0.89±0.07 |

|

53.0±0.56 |

83.9±0.9 |

0.57±0.13 |

≤17.2 |

0.90±0.08 |

|

Ordering Size (RSFR-M-2X/3X) |

Ladder Format Type |

Continuous Type |

|---|---|---|

Small Box Packing (PCS/Box) |

||

Φ2.4 |

2500 |

50 |

Φ3.2 |

2000 |

100 |

Φ4.8 |

2000 |

100 |

Φ6.4 |

2000 |

100 |

Φ9.5 |

1000 |

100 |

Φ12.7 |

1000 |

100 |

Φ19 |

500 |

100 |

Φ25 |

500 |

100 |

Φ38 |

500 |

50 |

Φ51 |

250 |

50 |

Property |

Unit |

Testing Requirement |

WOER Results |

|---|---|---|---|

Tensile strength |

MPa |

10.3 |

14.3 |

Ultimate elongation |

% |

200 |

330 |

Low temperature flexibility |

- |

No cracking |

Pass(no cracking) |

4 hours at |

kV/mm |

19.7 |

20 |

Dielectric strength |

Ω·cm |

101 4 |

2.0×101 4 |

Volume Resistivity |

- |

No corrosive |

pass |

Corrosive effect |

- |

168 hours at 158±2℃ |

Pass(no cracking, print is legible) |

Heat aging |

Rubs |

Pass(legible after 100 rubs) |

|

Print performance |

Strokes |

Pass(legible after 100 Strokes) |

RSFR-M-3X-4.8-50-2.0K-Y 0 P2 W

Package:W for WOLABLE painting package.O for OEM package

Printing:PO/P1/P2 for printing/single-side printing/ double-side printing.

Dash line:0/1/2/3......for not need/one line/two-line/three-line......

Color:Y for yellow, W for white and ten colors are available

Standard pack:2.5K/2K/1.5K/1K/0.5K/0.25K/for 2500/....../500 and 250 pieces

Sleeve length:nominal length is 50mm(the total length is 56.5mm)

Expanded ID:as supplid,nominal inside diameter

Expansion ratio:2X/3X refers to 2:1 or 3:1

Standard wall thickness

Product family:RSFR refers to UL 224

|

Color code |

BL |

Br |

R |

Or |

Y |

G |

Blu |

V |

Gr |

W |

|---|---|---|---|---|---|---|---|---|---|---|

|

Color |

Black |

Brown |

Red |

Orange |

Yellow |

Green |

Blue |

Violet |

Grey |

White |

Note: Yellow and white are standard, other color is available if ordered.

Description: According to the structure of label card, the identification tag is made of environment-friendly polyolefin material by means of bombardment and cross-link of high energy electron bunch.

They are mainly applied in the domains such as high-trials, subways, MU train nuclear power station, airplane and space shuttles where the wide-diameter cable and bundle labels with high reliability are required to applied, especially in severe environment.

Use: Markers can be easily removed from the carrier, and applied to cables and wire bundles using cable dies. Thermal transfer printer and WO-80500BK ribbon are recommended for meeting printing performance requirements of SAE AS 81531 and MIL-STD-202F.

|

Properties |

AMS |

HMS |

HNF |

RSFR |

Test Method |

|---|---|---|---|---|---|

|

Tensile strength (MPa) |

≥10.3 |

≥13.8 |

≥10.3 |

≥10.3 |

ASTM D2671 |

|

Tensile strength after aging (MPa) |

≥6.9 |

≥11.1 |

≥6.9 |

≥6.9 |

ASTM D2671 |

|

Ultimate elongation after aging(%) |

≥200 |

≥200 |

≥200 |

≥200 |

ASTM D2671 |

|

Ultimate elongation(%) |

≥100 |

≥100 |

≥100 |

≥100 |

ASTM D2671 |

|

Voltage withstand(V) |

2500 V,60s,Pass |

2500 V,60s,Pass |

2500 V,60s,Pass |

2500 V,60s,Pass |

Ul224 |

|

Dielectric strength (MV/m) |

≥19.7 |

≥19.7 |

≥19.7 |

≥19.7 |

ASTM D2671 |

|

Volume resistivity(Ω·cm) |

≥101 4 |

≥101 4 |

≥101 4 |

≥101 4 |

ASTM D2671 |

|

Water absorption(%) |

≤0.5 |

≤0.5 |

≤1.0 |

≤1.0 |

ASTM D570 |

|

Corrosion |

Pass |

Pass |

Pass |

Pass |

UL 224 |

|

Heat shock |

No cracks, flowing or dripping |

No cracks, flowing or dripping |

No cracks, flowing or dripping |

No cracks, flowing or dripping |

UL 224 |

|

Low temperature flexibility |

No cracks |

No cracks |

No cracks |

No cracks |

UL 224 |

|

Flammability |

|

|

|

60s

|

UL 224 DIN5510-2 |

|

Smoke density Ao |

NG |

NG |

0.17 |

NG |

BS6853 |

|

Index of toxic fume R |

NG |

NG |

0.56 |

NG |

BS6853 |

|

Order Code |

Pack size (pcs/coil) |

Marker high (mm) |

Marker length (mm) |

|---|---|---|---|

|

|

2000 |

10.4 |

45 |

|

|

2000 |

10.4 |

53 |

|

|

2000 |

10.4 |

64 |

|

|

2000 |

10.4 |

76 |

|

|

2000 |

10.4 |

90 |

|

|

2000 |

12.0 |

102 |

|

|

1500 |

15.0 |

45 |

|

|

1500 |

15.0 |

53 |

|

|

1500 |

15.0 |

64 |

|

|

1500 |

15.0 |

76 |

|

|

1500 |

15.0 |

90 |

|

|

1000 |

20.3 |

45 |

|

|

1000 |

20.3 |

53 |

|

|

1000 |

20.3 |

64 |

|

|

1000 |

20.3 |

76 |

|

|

1000 |

20.3 |

90 |

|

|

1000 |

25.4 |

45 |

|

|

1000 |

25.4 |

53 |

|

|

1000 |

25.4 |

64 |

|

|

1000 |

25.4 |

76 |

|

|

1000 |

25.4 |

90 |

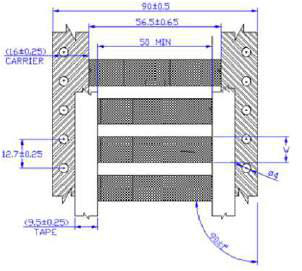

HMS-M-4H-10.4-38-2.0K-Y A P2 W

Package:W for WOLABLE painting package.O for OEM package

Printing:P0/P1/P2 for printing/single-side printing/ double-side printing

Dash line:0/1/2/3......for not need/one line/two-line/three-line......

Color:Y for yellow, W for white and ten colors are available

Standard pack:2.5K/2K/1.5K/1K/0.5K/0.25K/for 2500/....../500 and 250 pieces

Tag length: tag length is 38mm

Tag height: tag height is 10.4mm

Amount of holes:4H/6H refer to 4 holes and 6 holes

Product family:HMS

Standard wall thickness

Description & application: WO-80500BK (N85)— is an ultra- high durability black resin thermal transfer ribbon, tested and approved for use on WOER AMS-M, HMS-M, DIN-M and HNF-M wire marker sleeves as well as RSFR/AMS/HMS/HNF cable marker tags. For reliable print performance and durability, please use WOER recommended compatible printers.

| Manufacturer: | WOER |

| The max storage temperature: | -5℃-40℃ |

| Operating temperature: | 5℃-35℃ |

| The delivery temperature: | +135℃ |

| Maximum storage temperature | -5℃-45℃ |

| Complied standards: | SAE AS 81531 and MIL-STD-202F/215J |

| Ribbon width: | 100 mm ;60mm;40mm |

| Ribbon length: | 300 m |

| Printable area: | 100% full area |

| Internal diameter: | 25mm |

| Outside diameter: | 62mm |

| Ink: | Resin |

| Standard color: | Black |

| Ribbon wind direction: | Ink exterior |

|

Properties |

Typical value |

|---|---|

|

Compatible printer: |

WO-III,110-600DPI |

|

|

|

|

Compatible materials: |

AMS, HMS, RSFR, HNF |