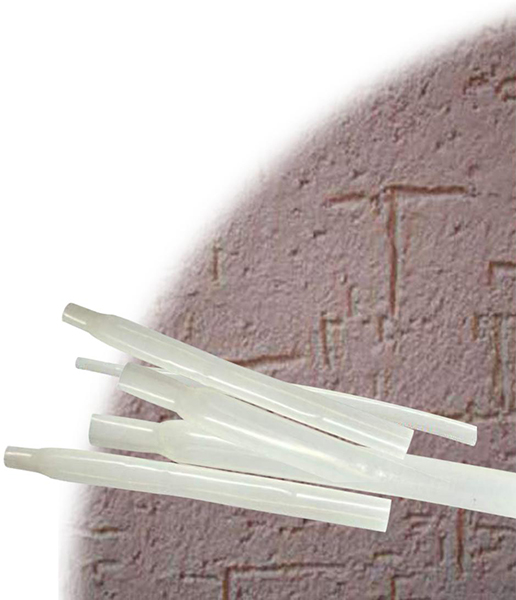

Heat Shrink Teflon Tubing can be widely used in science &technology field, such as chemistry, mechanical industries, astronautic industry, vehicles, transformers, communications, etc

Size (mm) |

Expanded |

Recovered |

Standard Package (m/spool) |

Round/Flat |

|

|---|---|---|---|---|---|

Internal Diameter (mm) |

Internal Diameter (mm) |

Wall Thickness (mm) |

|||

1.0 |

1.0±0.2 |

≤0.6 |

0.20±0.05 |

200 |

Round |

1.5 |

1.5±0.2 |

≤0.9 |

0.20±0.05 |

200 |

Round |

2.0 |

2.0±0.2 |

≤1.3 |

0.20±0.05 |

200 |

Round |

2.5 |

2.5±0.2 |

≤1.5 |

0.20±0.05 |

200 |

Round |

3.0 |

3.0±0.2 |

≤1.8 |

0.20±0.05 |

200 |

Round |

3.5 |

3.5±0.2 |

≤2.0 |

0.20±0.05 |

100 |

Round |

4.0 |

4.0±0.3 |

≤2.5 |

0.25±0.05 |

100 |

Round |

4.5 |

4.5±0.3 |

≤2.8 |

0.25±0.05 |

100 |

Round |

5.0 |

5.0±0.3 |

≤3.0 |

0.25±0.05 |

100 |

Round |

6.0 |

6.0±0.3 |

≤3.8 |

0.25±0.05 |

100 |

Round |

7.0 |

7.0±0.3 |

≤4.0 |

0.25±0.05 |

100 |

Round |

8.0 |

8.0±0.3 |

≤4.8 |

0.25±0.05 |

1 |

Flat |

9.0 |

9.0±0.3 |

≤5.0 |

0.30±0.05 |

1 |

Flat |

10.0 |

10.0±0.3 |

≤5.8 |

0.30±0.05 |

1 |

Flat |

11.0 |

11.0±0.3 |

≤6.4 |

0.30±0.05 |

1 |

Flat |

12.0 |

12.0±0.3 |

≤7.0 |

0.30±0.05 |

1 |

Flat |

13.0 |

13.0±0.3 |

≤7.5 |

0.35±0.05 |

1 |

Flat |

14.0 |

14.0±0.3 |

≤8.0 |

0.35±0.05 |

1 |

Flat |

15.0 |

15.0±0.3 |

≤8.5 |

0.40±0.05 |

1 |

Flat |

16.0 |

16.0±0.3 |

≤9.0 |

0.40±0.05 |

1 |

Flat |

Property |

Method Test |

Typical Performance |

|---|---|---|

Tensile Strengtn(MPa) |

ASTMD 2671 |

19 |

Elongation(%) |

ASTMD 2671 |

200 |

Cold impact |

ASTMD 2671 Method C |

No cracking |

Flammablity |

ASTMD 2671 |

|

Dielectric strength(kV/mm) |

VDE 0303 Part2 |

26 |

Volume resistivity(Ω.cm) |

VDE 0303 Part2 |

1.0X101 4 |

Transparent, thin wall PVDF (polyvinylidene fluoride) heat shrink tubing ideal for electronic, automotive and military applications requiring protection and see-through inspection in aggressive environments

Size |

Expanded |

Recovered |

Standard Package M/Spool |

Round/Flat |

||

|---|---|---|---|---|---|---|

Inch |

mm |

Internal Diameter (mm) |

Internal Diameter (mm) |

Wall Thickness (mm) |

||

3/64 |

1.2 |

1.2 |

0.6 |

0.25±0.05 |

200 |

Round |

1/16 |

1.6 |

1.6 |

0.8 |

0.25±0.05 |

200 |

Round |

3/32 |

2.4 |

2.4 |

1.2 |

0.25±0.05 |

200 |

Round |

1/8 |

3.2 |

3.2 |

1.6 |

0.25±0.05 |

200 |

Round |

3/16 |

4.8 |

4.8 |

2.4 |

0.25±0.05 |

100 |

Round |

1/4 |

6.4 |

6.4 |

3.2 |

0.30±0.05 |

100 |

Round |

3/8 |

9.5 |

9.5 |

4.8 |

0.30±0.05 |

50 |

Round |

1/ 2 |

12.7 |

12.7 |

6.4 |

0.30±0.05 |

50 |

Round |

3/4 |

19.1 |

19.1 |

9.5 |

0.42±0.05 |

50 |

Round |

1 |

25.4 |

25.4 |

12.7 |

0.50±0.05 |

50 |

Round |

38.1 |

38.1 |

19.1 |

0.50±0.05 |

50 |

Round |

|

Note: 3:1 shrink ratio is available upon request

Property |

Test Method |

Typical Performance |

|---|---|---|

Tensile Strengtn(MPa) |

ASTM D 2671 |

≥30 |

Elongation(%) |

ASTM D 2671 |

≥150 |

Tensile |

250℃X168hr |

≥100 |

Cold Bend |

No cracking |

≥220 |

Flammability |

ASTM D 2671 |

|

Volume resistivity(Ω.cm) |

IEC 60093 |

≥101 4 |

Thin wall Viton fluoroelastomer heat shrink tubing suitable for use in electronic systems and components in automotive, military/ aerospace and industrial applications requiring outstanding heat and fluid resistance.

|

Size |

Expanded |

Recovered |

Standard Package M/Spool |

Round/Flat |

||

|---|---|---|---|---|---|---|

|

Inch |

mm |

Internal Diameter (mm) |

Internal Diameter (mm) |

Wall Thickness (mm) |

||

|

3/32 |

2.4 |

2.4 |

1.2 |

0.70±0.20 |

200 |

Round |

|

1/8 |

3.2 |

3.2 |

1.6 |

0.75±0.20 |

200 |

Round |

|

3/16 |

4.8 |

4.8 |

2.4 |

0.89±0.20 |

100 |

Round |

|

1/4 |

6.4 |

6.4 |

3.2 |

0.89±0.20 |

100 |

Round |

|

3/8 |

9.5 |

9.5 |

4.8 |

0.89±0.20 |

50 |

Flat |

|

1/ 2 |

12.7 |

12.7 |

6.4 |

0.89±0.20 |

25 |

Flat |

|

3/4 |

19.0 |

19.0 |

9.5 |

1.07±0.30 |

25 |

Flat |

|

1 |

25.4 |

25.4 |

12.7 |

1.25±0.30 |

25 |

Flat |

|

|

38.1 |

38.1 |

19.0 |

1.40±0.30 |

25 |

Flat |

|

2 |

50.8 |

51.0 |

25.4 |

1.65±0.30 |

15 |

Flat |

Note: 3:1 shrink ratio is available upon request

|

Property |

Test Method |

Standard |

Typical Performance |

|---|---|---|---|

|

Tensile Strengtn(MPa) |

ASTM D2671 |

≥8.5 |

10.0 |

|

Elongation(%) |

ASTM D2671 |

≥250 |

300 |

|

Tensile Strengtn after aging (MPa) |

UL224 158 X168hr |

≥7.3 |

8.5 |

|

Elongation after aging(%) |

UL224 158 X168hr |

≥200 |

250 |

|

Dieletric strength(kV/mm) |

IEC 60243 |

≥15 |

17.5 |

|

Volume resistivity(Ω.cm) |

IEC 60093 |

≥1X109 |

2.5X109 |

|

Flammability |

Ul224 |

Pass |

Pass |

Specially designed for protecting applications in extreme electrical Chemical and thermal environment

|

Size AWG |

Expanded |

After Recovery |

Standard Package M/Spool |

||

|---|---|---|---|---|---|

|

Internal Diameter mm |

(S) |

(T) |

(L) |

||

|

30 |

0.30±0.10 |

0.80±0.10 |

0.70±0.10 |

0.60±0.10 |

305 |

|

28 |

0.38±0.10 |

0.88±0.10 |

0.78±0.10 |

0.68±0.10 |

305 |

|

26 |

0.46±0.10 |

0.96±0.10 |

0.86±0.10 |

0.76±0.10 |

305 |

|

24 |

0.56±0.10 |

1.16±0.10 |

1.06±0.10 |

0.86±0.10 |

305 |

|

23 |

0.66±0.10 |

1.26±0.10 |

1.16±0.10 |

0.96±0.10 |

305 |

|

22 |

0.71±0.10 |

1.31±0.10 |

1.21±0.10 |

1.01±0.10 |

305 |

|

21 |

0.81±0.10 |

1.41±0.10 |

1.31±0.10 |

1.11±0.10 |

305 |

|

20 |

0.86±0.10 |

1.66±0.10 |

1.46±0.10 |

1.16±0.10 |

305 |

|

19 |

0.96±0.20 |

1.76±0.20 |

1.56±0.20 |

1.26±0.20 |

200 |

|

18 |

1.07±0.20 |

1.87±0.20 |

1.67±0.20 |

1.37±0.20 |

200 |

|

17 |

1.19±0.20 |

1.99±0.20 |

1.79±0.20 |

1.49±0.20 |

200 |

|

16 |

1.34±0.20 |

2.14±0.20 |

1.94±0.20 |

1.64±0.20 |

153 |

|

15 |

1.50±0.20 |

2.30±0.20 |

2.10±0.20 |

1.80±0.20 |

153 |

|

14 |

1.68±0.20 |

2.48±0.20 |

2.28±0.20 |

2.08±0.20 |

100 |

|

13 |

1.93±0.20 |

2.73±0.20 |

2.53±0.20 |

2.33±0.20 |

100 |

|

12 |

2.16±0.25 |

2.96±0.25 |

2.76±0.25 |

2.56±0.25 |

100 |

|

11 |

2.41±0.25 |

3.21±0.25 |

3.01±0.25 |

2.81±0.25 |

150 |

|

10 |

2.86±0.25 |

3.49±0.25 |

3.29±0.25 |

3.09±0.25 |

150 |

|

9 |

3.00±0.25 |

4.00±0.25 |

3.80±0.25 |

3.40±0.25 |

150 |

|

8 |

3.38±0.25 |

4.38±0.25 |

4.18±0.25 |

3.78±0.25 |

100 |

|

7 |

3.76±0.25 |

4.76±0.25 |

4.56±0.25 |

4.16±0.25 |

100 |

|

6 |

4.22±0.25 |

5.22±0.25 |

5.02±0.25 |

4.80±0.25 |

100 |

|

5 |

4.72±0.25 |

5.72±0.25 |

5.52±0.25 |

5.32±0.25 |

50 |

|

4 |

5.28±0.30 |

6.28±0.30 |

6.08±0.30 |

5.88±0.25 |

50 |

|

3 |

5.94±0.30 |

6.94±0.30 |

6.74±0.30 |

6.54±0.25 |

1.00 |

|

2 |

6.68±0.30 |

7.68±0.30 |

7.48±0.30 |

7.28±0.25 |

1.00 |

|

1 |

7.46±0.30 |

8.46±0.30 |

8.26±0.30 |

8.06±0.25 |

1.00 |

|

0 |

8.38±0.30 |

9.38±0.30 |

9.18±0.30 |

8.98±0.25 |

1.00 |

Property |

Method Test |

Standard |

|---|---|---|

Tensile Strengtn(MPa) |

ASTMD 2671 |

≥25 |

Elongation(%) |

ASTMD 2671 |

≥300 |

Flammablity |

Pass |

|

Dieletric strength(kV/mm) |

IEC 60243 |

≥26 |

Volume resistivity(Ω.cm) |

IEC 60093 |

≥1X101 4 |